Distilleries are embracing technology to enhance efficiency and streamline operations. Barrel Scanning solutions are one such technology solution which is growing in popularity, simplifying barrel management processes whilst allowing for greater flexibility and accuracy.

From improving productivity and space utilisation to enabling real-time tracking of barrel movements and the validation of specified barrels for inclusion in operations, scanning solutions revolutionizing how distilleries manage their barrels and optimize their warehouse processes.

Enhanced Barrel Management

With hundreds, thousands, and sometimes even hundreds of thousands of barrels being stored on a distillery site, ensuring an accurate and efficient barrel management process becomes a critical element of distillery operations.

Barrel scanning solutions offer several advantages in this area. By affixing unique identifiers, such as barcodes or RFID tags, to each barrel, distilleries can accurately track their location, contents, age and history. This real-time transfer of barrel location and movement information from the warehouse to the central inventory management solution eliminates manual record-keeping and reduces the risk of errors. With an integrated scanning solution in place, distillers are able to increase the accuracy of their inventory data and enhance their barrel management processes.

Streamlined Warehouse Processes

Efficient warehouse processes are essential for distilleries to successfully manage a maturing spirit inventory, optimize warehouse space utilisation and optimise the deployment of warehouse operators and equipment to complete distillery operations.

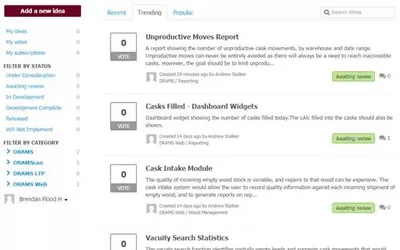

With an integration between a barrel scanning solution and a distillery management solution, distilleries can gain real insights into warehouse, inventory and operator performance metrics which can be used to support warehouse process improvements.

For example, operators can easily gain visibility of warehouse capacity, vacuity, utilisation, and inventory distribution, enabling improved decision making in a number of warehouse operational processes. Including, for example, inventory put-away and/or retrieval operations, the consolidation of existing inventory for improved warehouse utilisation or the distribution of inventory across a warehouse/site for product quality or for fail safe reasons.

Overall, by implementing scanning solutions in their warehouse operations distilleries can streamline the overall handling of barrels maturing within the warehouse.

Improved Productivity and Time Savings

Scanning solutions can be used to significantly enhance productivity and save valuable time for distilleries. Manual data entry and paperwork are eliminated as scanning technology automates the upload of barrel location data to central inventory management solution, reducing human error and increasing efficiency.

By simply scanning barcodes or RFID tags, distilleries can capture, and record data related to barrel movements and warehouse activities.

Additionally, scanning solutions also allow data to be captured relating to operator performance in comparison to organisational targets. For example, in addition to capturing the updated inventory values, report can be used to track the number of each scan transaction completed within a given period of time by each operator, i.e allowing distilleries to monitor the number of barrels stowed into a warehouse or removed from storage against the organisation targets.

The hand-held scanner devices can also be used to notify the operator of barrels wrongly selected for an ongoing operation in real time – allowing the mistake to be quickly rectified and prevent knock-on delays in the process.

The time saved by utilising scanning solutions can be redirected towards other critical tasks, ultimately improving overall productivity.

Real-time Tracking and Validation of Operations

Scanning solutions enable distilleries to track barrels and validate operations in real-time. Work orders can be downloaded from the barrel inventory management solution onto the hand-held scanner devices, allowing operators to be directed to the exact inventory or warehouse location. Minimising delays and ensuring efficient workflows are maintained in barrel put-away and/or retrieval exercises.

Barrel scanning solutions also enable validation of barrels against the downloaded work order, ensuring that the right barrel is used for specific operational processes. This validation enhances accuracy, reduces the risk of errors, and maintains product consistency, particularly when used to validate the barrels selected for inclusion in a dumping operation.

Implementing scanning solutions in distilleries for barrel management and warehouse processes brings numerous advantages, including enhanced barrel management, streamlined warehouse operations, improved productivity, time savings, and increased accuracy of inventory data. By embracing scanning technology, distilleries can optimise their processes, reduce costs, and minimise the opportunities for error. The use of scanning solutions revolutionizes how distilleries manage their barrels and warehouses, positioning them for success in an evolving and competitive industry.

For more information about implementing a scanning solution to support your barrel management & warehousing processes, watch the recording of our recent webinar.