When speaking with prospective customers, we occasionally hear of the organisation’s existing ERP solution as a possible reason not to invest in DRAMS. This viewpoint betrays a misconception regarding what precisely a tailored distillery management solution does, and how it works within the overall operations management framework.

It is undeniable that an ERP system is an invaluable platform for managing the various processes which are essential to running a business. But that’s just it; an ERP handles the processes which are critical to ‘a’ business; but not the specific requirements of the matured spirits industry.

Used by organisations to manage day-to-day business activities such as accounting, procurement, project and performance management, most ERP solutions are designed to facilitate the more generalised business processes. Even those with the functionality to manage manufacturing and supply chain operations lack the transactional detail required to accurately record the maturation and movement of a bulk spirits inventory.

This lack of detail means that they are unable to provide distillery managers with access to centralised cask level information or visibility of location, content and value for every barrel in the warehouse. As a result, tasks take longer than they should, and costly mistakes can quickly occur.

While an ERP system supports the broader business functions; this missing functionality forms a noticeable gap in the management of distillery operations –at both the day-to-day and overall strategy level.

With significant investments having already been made into the implementation and management of an ERP solution, the question of how to bridge this operational gap is one we commonly hear from prospective customers.

In short, there are two answers. The first, to extend the functionality of your existing ERP through custom development. Alternatively, to select an industry-specific software solution which can interface directly with your ERP.

The challenges of customising an ERP system

There are merits to the customisation approach, but extending the functionality of your ERP is not without its challenges.

While any custom-built functionality will be designed with your specific business processes in mind, the benefits gained from a completely bespoke solution can sometimes be marred by the resources required to design, create and maintain such a “perfect fit” solution.

Some of the critical challenges associated with creating bespoke ERP functionality include:

Calculating the total cost of ownership: The customisation of your ERP solution is likely to require significant consultancy and development costs and more often than not you will be reliant on consultants who don’t fully understand your industry or ways of working. To enable this team to design a solution which meets your brief will require a substantial investment of time from you and your colleagues, redirecting critical resource away from day-to-day operations.

On the other hand, if you were to bring the development in house, you would need to consider the costs associated with recruiting and hiring the expertise required to complete the bespoke development. Alternatively, if you would prefer that the responsibility of completing such an important project be given to an existing team member, it would be worth considering how much resource will be diverted from standard business activities and if this will need to be supplemented by a new-hire.

Accepting the risk of failure: By choosing to go down the route of custom development, distilleries must also take the risk that the end result may not meet their needs. Additionally, when designing custom-built functionality based on end-user insights, distillers must bear in mind the need to create processes which provide overall performance improvements as opposed to just creating shortcuts which enable inefficient processes to be completed faster. Consequently, having been designed from within the organisation, the resulting system will likely fail to leverage shared industry insights and best practices. Also, it may ultimately reinforce wasteful or error-prone habits.

Issues with Upgrades: The development of even a standard ERP package requires significant engineering. Careful consideration must be made to ensure any custom development does not jeopardise the architecture of the core system. Bespoke development which compromises the integrity of the original software, will severely restrict the potential for future enhancements or ongoing development. It is for these reasons that ERP providers are unable to maintain bespoke customisation in future product releases, which results in distillers being forced to maintain legacy systems without a clear upgrade path. As the solution is designed to facilitate a multitude of business processes and functions, this can limit the wider organisation, and not just distillery operations where the bespoke functionality was required. To gain access to the new features, distillers must face the substantial costs associated with re-implementing the bespoke areas of functionality in addition to the standard ERP upgrade costs.

Issues with long term support: Ongoing solutions support is essential, especially when these systems relate to the delivery of business-critical operations. Working with the original vendor or partner to develop the bespoke functionality will enable them to provide support services; however, once again, their existing knowledge of sophisticated distillery and maturation processes could prove limiting. Alternatively, for distilleries who choose to develop the custom functionality in-house, the industry knowledge of their existing team is likely to be a significant asset should complications arise. However, organisations must consider the knowledge or skills gaps which are likely to occur when an employee leaves. It is also worth considering if the bespoke development will complicate the ability of the original ERP vendor or partner to provide support capabilities relating to the core product.

The Burden of Maintenance: Distillers who go down the route of designing custom functionality will not only face the challenges associated with upgrading the core functionality but also experience additional complications when considering how to further enhance their customisations. Unless you retain a dedicated development team, the resulting solution is likely to remain static, un-supported and extremely difficult to upgrade. Taking the functionality forward will require resources to be continually devoted to the project, costing significant time and money.

Ongoing employee training: The bespoke customisation of the ERP solution means that the resulting functionality is inherently one of a kind. This uniqueness means that it can be problematic when onboarding new employees or dealing with staff turnover. The uniqueness of the solution means that the knowledge of its infrastructure and proper use is likely to be limited to the individuals involved in its development, making it a challenge to provide ongoing training and support to new employees.

Consider the Benefits of Choosing an Industry Partner

Ultimately, the spirit management system implemented by a distillery should be one which supports the strategic vision of the organisation and will provide a solution which will quickly scale in line with the changing needs of the business. For some, the answer may lie in the bespoke development of their existing ERP infrastructure.

However, there is another option. Many distilleries find that by choosing a partner to implement an industry-specific solution they are able benefit from a software platform which provides the best of both words. Access to the essential functionality not included in a standard ERP package but with none of the drawbacks associated with a bespoke development project.

The out-of-the-box functionality of an industry solution has been specifically designed to cope with the nuances of the matured spirit industry which means that it can immediately begin to bridge the gap in distillery operational processes. With over 40 years of industry experience, DRAMS has worked with many spirit producers around the world to understand their needs and to address their requirements. The platform has been designed to facilitate the complex processes involved in the movement, maturation and storage of a bulk spirit inventory. As a tried and tested solution, it has proven results in the Whisk(e)y, Rum and Tequila sectors. A success, which can be largely attributed to the exceptional services provided by the DRAMS team and our ability to identify the underlying commonality in the challenges faced by mature spirit suppliers around the globe.

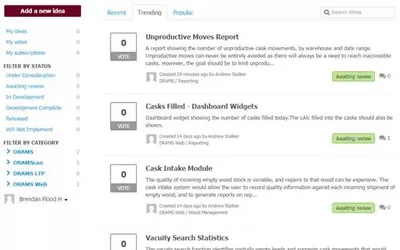

The collaborative approach that we have with our customers, supplemented by the extensive industry and systems knowledge of our team has allowed us to develop a solution which leverages industry best practice and can be used to address the gap in the technology required for the management of distillery processes However, we also ensure that a level of flexibility is maintained within the system, allowing our customers to adapt the solution to reflect their own circumstances and to retain their unique perspective of the processes required for the production, maturation and movement of a bulk spirit inventory.

Some of the other benefits of choosing DRAMS as an industry partner include:

Implementation time: By leveraging an industry-specific solution, the time required to implement the system will be significantly less than it would be if you were to develop your own This reduced implementation time means that you can begin benefiting from the enhanced operational processes in a timelier fashion, and more importantly, this means that the journey to realising the ROI of your investment will also begin much earlier.

Integrations for multiple layers of visibility: DRAMS has a proven track record of working with ERP solutions such as SAP, IFS Applications, and JD Edwards to ensure a seamless integration. Through this interface, users can ensure that a high-level view of spirit inventory is maintained within the ERP system but without the added detail required to complete operational tasks. This integration means the wider business functions still retain access to crucial information but that the ongoing management of daily operations is delivered within a system which caters to the unique processes involved.

For more insights into our integrations capabilities, read our case study here.

Bespoke Functionality: While one of the key benefits of the DRAMS solution, is its out-of-the-box functionality, we also recognise that some distillers may have unique processes or requirements. To provide our customers with a solution which will meet all of their needs, the DRAMS development team is well versed in adapting the existing solution to meet custom requirements or to deliver bespoke functionality.

Applications Maintenance Model: DRAMS ensures that all of your customisations are maintained in future product releases, making the upgrade path extremely straight forward. In addition to this, we are continually investing in the DRAMS product, which means that product upgrades introduce welcome new features. The DRAMS product set is also continually expanding as we work with our existing customers to design new modular functionality.

Industry Partner and Community: We aim to become a trusted partner for all our customers, and to develop a mutually beneficial relationship. As part of this DRAMS hosts an annual User Group event offering our customers the ability to share information and knowledge with the broader community. The insights gained at these events from the collaboration of all our customers, new and old, guides the future direction of the product.

Dedicated Customer Support and Training: Whether it is two months or two years after implementation, should you have a problem or query our Customer Care Team are on hand to provide dedicated support. All members of the team are experts in the DRAMS product and have years of industry experience; allowing them to quickly familiarise themselves with your internal processes and to offer insights and guidance as you need them. Additionally, with each DRAMS implementation, we provide a thorough on-boarding and training service to ensure your team are equipped to use the platform. And post-implementation, additional training can be provided for a variety of circumstances including new staff on-boarding, data analysis, data entry, employee advancement training or bespoke requirements.

For distillers who are currently experiencing challenges associated with a lack of systems functionality and a gap in their operational process management, then the question is no longer whether to invest, but where to invest.

Evaluating the pros and cons of a ‘build’ or ‘buy’ approach is essential in deciding where your business will most benefit from such an investment as the resulting solution must meet the long-term strategy of the business.

The challenges and costs associated with choosing to design and develop bespoke functionality must be weighed against the perceived benefits of owning and maintaining a wholly unique solution. While also considering that the customisation a software solution which currently services the entire business is not without its risks.

Alternatively, when choosing to partner with an industry specialist, you can be assured of the systems capabilities and the satisfaction of existing customers before implementation begins. While also remaining confident that throughout the engagement process you will be able to discuss your requirements and concerns with an industry peer who understands your experiences and is equipped to provide the information you need.

If you’re currently considering a solution to support your bulk spirit inventory and warehouse management processes and are not sure where to invest, speak to a DRAMS consultant today for more information. Alternatively, to learn more about the benefits of the DRAMS solution request a DEMO using our contact us page here.