The Challenge

In order for producers of spirits to consistently meet targets in line with their long-term production plans, they need to effectively manage their component spirit recipes and ingredients in order to create the necessary blends of their spirits. Recipes for all spirit blends can be complex – for example, whisky recipes may include two or three malts and a grain or any variety of potential combinations. This is easier said than done, of course. Because not only can recipes prove to be incredibly complex, they can also vary based on external factors that must be considered. For example, if a recipe depends on a certain ingredient of which stocks are running low – for instance a peated whisky last produced in 1986 – then managers need to factor in the predicted loss of this ingredient to their five, ten or fifteen year bottling plans. They must further establish whether it is possible to substitute one ingredient (which will soon run out) for another, ensuring the new ingredient matches the previous ingredient’s age and flavour profile. Stock and warehouse managers must therefore take into account existing stock, and evaluate whether they have enough to serve as ingredients in their blending plans as they strive to meet five, ten, 15 or even 25 year bottling production plans and targets. It is vital that managers are able to base their evaluation and reports on accurate, up-to-date data, and gauge a holistic understanding of their stocks. This informs critical strategic decision making, including whether it will be necessary to purchase and use third party spirits from other distilleries and warehouses.

The Solution

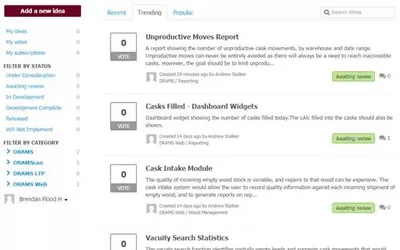

Modern software solutions enable managers to effortlessly manage complex processes and challenges, such as managing spirit recipes and ingredients. The Long Term Planning module for DRAMS provides businesses with an overview of their operations, enabling organisations to take corrective action if they need to make adjustments. For example, the module will highlight where stock ingredients are low, so that managers can make adjustments to their recipes. Using the LTP module also provides managers with the accurate, quality data they need to make key strategic decisions. By providing them with an up-to-date picture of their existing stocks and ingredients, the system ensures spirits producers can consistently meet their long-term production targets and plans, creating great tasting high quality spirit recipes that customers love.