Distilleries Implementing Technological Solutions

In today’s rapidly evolving world, the implementation of advanced technologies has become crucial for industries across various sectors. Distilleries, too, have embraced modern solutions to enhance efficiency and ensure product quality. One such technology is scanning solutions, which offer numerous benefits, including improved inventory management, enhanced spirit traceability, and streamlined operations.

However, implementing scanning solutions in distilleries comes with its own set of challenges. In this article, we will explore these challenges and discuss strategies to overcome them, enabling distilleries to leverage the full potential of scanning solutions.

Integration with Inventory Management Systems

One of the primary challenges distilleries face when implementing scanning solutions is integrating them with their existing systems. Distilleries typically have complex processes and multiple systems in place, such as enterprise resource planning (ERP) software and inventory management systems. Ensuring seamless integration between these systems and scanning solutions is essential for effective data management and process optimisation.

To overcome this challenge, distilleries should collaborate closely with technology providers to choose scanning solutions capable of integrating with their existing infrastructure, allowing for smooth data exchange and minimising disruptions during the implementation process.

Choosing a Label Type – Barcodes vs RFID Tags

When considering the implementation of scanning solutions in distilleries, it is essential to evaluate the merits of utilising either barcodes or RFID tags as the barrel identification method. Both options have their merits and should be carefully assessed based on the distillery’s specific requirements.

Barcoding is a safe, reliable, and straight-forward barrel labelling option, providing a cost-effective and widely adopted solution for inventory tracking and management. Barcode labels can be easily generated, printed, and affixed to the relevant barrels, and the universal nature of barcoding means that no special scanner technology is needed to read the label.

On the other hand, RFID (Radio Frequency Identification) tags can be seen to offer several additional benefits. RFID tags can store more information than barcodes and can be read from a greater distance, enabling efficient scanning of multiple items simultaneously, even without a direct line of sight between scanner and label.

However, in a distillery warehouse, where the primary aim is to improve inventory data accuracy, the ability to scan and track each barrel as an individual is much more beneficial – making barcodes the more optimal choice.

Measures can be taken to limit the multi-path scanning of an RFID scanner by creating scanning areas or enclosures using RF shielding materials. While not appropriate for a warehouse, this can have a use case in a distillery environment – for example validating barrels within a disgorging area for inclusion in a dumping operation.

Evaluating the benefits of each labelling approach and how these correlates to a distilleries existing operational process can provide insight into which label type offers the most optimal solution.

Barcode and Labelling Standardisation

Barcode and barrel labelling standardisation is another significant challenge faced by distilleries during the implementation of scanning solutions. Inconsistencies in barcodes and labels can lead to errors in scanning, causing delays, inaccuracies, and operational inefficiencies.

To address this challenge, distilleries must establish standardised barcode and labelling practices. Implementing industry-recognised barcode formats – such as the format recommended by the SWA for the Scotch industry – ensuring proper placement, legibility and longevity of barrel labels will significantly improve scanning accuracy and overall operational efficiency.

Environmental Factors and Equipment Selection

Distilleries often operate in demanding environmental conditions, such as temperature variations and exposure to liquids and spirit vapours. These factors have an implication on the scanner hardware which can and should be used in a distillery environment.

In some countries there is legislative guidance on the types of scanner devices which should be used, while in others it is recommended best practice.

Zone 1 scanners are engineered to operate safely in potentially explosive atmospheres with the presence of flammable gases, vapours, or liquids. In a distillery environment, this type of device is recommended for use in areas where there is likely to be high concentrations of alcohol vapours, such as the dumping area.

For less extreme but still potentially hazardous environments, Zone 2 scanners offer a suitable solution. These scanners are designed to be used in areas where flammable substances are stored or handled – such as a distillery warehouse – but the risk of an explosive atmosphere is lower.

Understanding existing operational processes, the environmental conditions and how these will be impacted by the introduction of a scanning solution is an important step in ensuring the selection of the most appropriate scanner hardware.

It is always recommended for distilleries to consult with industry experts and comply with local safety regulations to determine how a scanning solution can be implemented to best optimise a distillery’s operational processes.

Employee Training and Adoption

Introducing new scanning solutions requires adequate training and adoption by distillery employees. Resistance to change, lack of familiarity with technology, and fear of increasing the complexity of the existing workload can hinder a successful implementation of scanning solutions.

Distilleries should prioritise comprehensive training programs to educate employees about the benefits of scanning solutions, demonstrate their ease of use, and address any concerns, highlighting the benefits to be gained by both the individual employee and the business. Involving employees in the decision-making process and fostering a culture of continuous learning and adaptation can promote acceptance and maximise the utilisation of scanning solutions.

Conclusion

Scanning solutions offer tremendous potential for distilleries to streamline operations, improve inventory management, and enhance product traceability. While implementing these solutions poses challenges, distilleries can overcome them. By working closely with industry experts and software solutions providers to address these challenges, distilleries can successfully implement scanning solutions and unlock the benefits they offer in the dynamic distillery landscape.

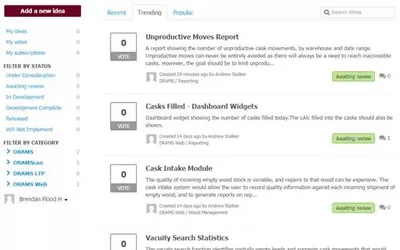

DRAMS Scan

Our DRAMS Scan module significantly streamlines the procedure for documenting barrel positions and transitions, enhancing data precision and optimising warehouse operations.

Seamlessly integrating with the DRAMS system, data is automatically transferred from the scanner to DRAMS whenever a network connection is established, guaranteeing the precise and effortless exchange of information.

For more information about DRAMS and all our available modules, download our product brochure, or speak to a consultant to arrange a demo.